Everything You Wanted to Know about Contactor Maintenance

[January 2015] There are many stresses on the broadcast transmission system, winter weather being but one of them. One critical part that needs attention at many stations is the contactor. Here is some information that may provide the answers you need.

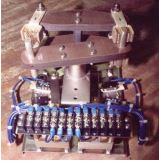

The contactor is a workhorse at the heart of most directional antennas, where they are most often found at tower bases and in phasors. They are also used to switch main and backup transmitters between the antenna and dummy loads.

When they are properly adjusted and working well, transmitter, power, and antenna mode changes are accomplished easily and reliably. When they fail, it can take a station off the air. One poorly maintained station had so many contactors fail that it took a man and a broom about half an hour to change power/pattern.

That makes regular inspection and maintenance important.

Stress Points

The contactors at tower bases are usually the most heavily stressed physically, especially the solenoids and finger stock.

The contactors at tower bases are usually the most heavily stressed physically, especially the solenoids and finger stock.

These parts have to deal with the dust and dirt, the wide changes in temperatures, humidity, and even lightning surges that happen at transmitter sites. They also have to deal with voltage variations from different causes.

Inside the phasor or transmitter switcher, the contactor’s finger stock usually is the most vulnerable, especially if the RF interlocks permit enough power to arc and burn the fingers. This often happens at stations where the interlocks are not set to kill the RF in order to shorten the brief interruption in programming during the switching. The interruption may be shorter, but there is definite damage to the fingers.

Maintenance Shift

As with any gear, a regular maintenance program will keep your contactors working better.

Visual observation, adjustment, and the occasional grease are the key points for normal operation. But when a solenoid fails or has insufficient pulling power or the finger stock gets burned or deformed, it is time to effect parts repair and replacement.

Because it is not if, but when, contactors will need maintenance, having a full set of spare parts on the shelf seems like a logical thing.

Unfortunately, too many stations do not have spare parts – hence the story above (sadly, not unique) of the station with the bad contactors, where power change was not only time consuming, but dangerous for the engineer, to keep a legal operation going.

A MAINTENANCE TUTORIAL

Kintronic Labs has put together a very nice half-hour of instruction on how best to repair/maintain your contactors.

The tutorial is presented by Maylo Echeverria, a contactor specialist at Kintronic Labs. Echevarria takes you through each part of a contactor, showing how to replace or adjust each one.

The tutorial is presented by Maylo Echeverria, a contactor specialist at Kintronic Labs. Echevarria takes you through each part of a contactor, showing how to replace or adjust each one.

If you are looking for a specific part of the assembly in the video, for a visual display on how to work with it, here are some timing marks on the video:

Approximate starting time for each part:

Solenoids: 0:26

Finger stocks and contact bar: 9:00 Micro-switches: 10:16

Linkage arms: 12:30

Tension adjustment: 12:47

Movable bar replacement: 16:00

Stationary bar replacement: 20:30

Finger stock adjustment 26:00

Of course, the Kintronic Labs folks are always ready to answer your questions, supply parts, or explain how to keep your contactors working at their best.