Reducing False Alarms From Remote Monitoring

[December 2020] Remote site management systems are designed to reduce maintenance personnel’s workload and ensure operational efficiency. However, if not properly set up or versatile enough, they can actually increase workloads by generating an abundance of false, or nuisance alarms. By analyzing what is happening, unnecessary alarms can be reduced or eliminated.

Remote site monitoring and control systems are generally recognized as being essential to the efficient operation of remote installations.

If properly installed and adjusted, the right system can help reduce trouble calls and/or off-air situations by alerting the engineering team of the exact issues at the site. Often, adjustments can be made remotely, saving loss of air time as well as travel time.

This is especially appreciated by the engineer (and mate) in the middle of a cold, stormy night!

The Remote That Cries “Wolf”

If not properly installed or adjusted – or having the wrong system in the first place – remote monitoring and control systems actually can reduce operational efficiency by sending false alarms.

Such false, or nuisance, alarms greatly reduce the usefulness of the remote system and eventually instill a mistrust of the remote management system, which could even go as far as ignoring alarms. After all, nobody likes being awoken needlessly in the middle of the night.

Having a system that “Cries Wolf” too often can be disastrous when a real alarm or emergency occurs.

This can lead to increased operating costs and even preventable system failures.

Solving the Problem

There are ways of ensuring that all alarms sent will be important ones and at severity levels that are proportional to the required remedial action.

Let us take a look at several means of attaining this goal of minimizing false alarms while still maintaining optimal site monitoring and control capabilities.

Techniques like de-glitching delays, hysteresis, software filtering, alarm aggregation, intelligent input qualification, and alarm redirection will help go a long way towards ensuring a system is operating optimally and is trusted and appreciated by site maintenance personnel.

By recognizing the sources of false alarms, you can become familiar with methods for minimizing them.

Eliminating Glitches

In many installations, the electrical system may be subject to fast transients and noise caused by equipment switching on and off.

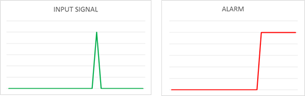

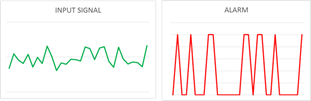

A fast-starting electric motor is one example of a device that can cause glitches on the network, and consequently on electronic equipment connected to it. These glitches can cause spurious alarms as shown in the figure below.

Input glitch and corresponding spurious alarm

Adding a 2-second de-glitching delay avoids alarms that could be triggered by electrical motor start-ups, power relay switching etc. as shown below.

The input glitch is ignored if it lasts less than 2 seconds

The input signal is validated

when present for more than 2 seconds

The goal is to adjust the delay to minimize glitches while capturing valid alarm conditions that occur.

An adjustment range between one second and several minutes (to account for various input conditions) usually will allow for best optimization.

For example, an audio silence of several seconds is probably ok (to account for pauses in speech and/or music), but an alarm is surely warranted after 20 to 30 seconds of silence.

Hysteresis

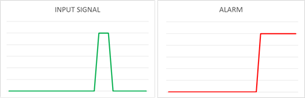

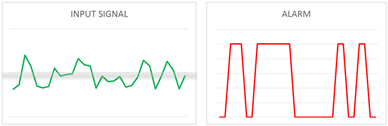

Monitoring a noisy input signal that varies closely around a trigger level, can cause multiple alarm on-off cycles as shown in the figure below.

A noisy input signal oscillating around

the alarm threshold causes multiple alarms

Adding hysteresis – allowing a lag in the signal change – creates a dead-zone around the trigger level. This ensures that an input signal must exceed the trigger level to set an alarm, and then it must return below a “reset” level to stop the alarm.

In the following example, the grey bar indicates a hysteresis range where the signal must exceed or fall below to trigger an alarm.

Exceeding the set level triggers an alarm,

then resets if the signal falls below the range

This reduces the number of alarm on-off cycles.

Filtering by Signal Averaging

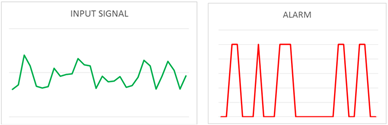

A noisy input signal can lead to multiple alarms as shown below.

Using an electronic filter could be one way of reducing these nuisance alarms, but adding a filtering circuit (soldering a capacitor and resistor for example) is not always easy or even possible.

Using a mathematical averaging function is the next best thing. Calculating a running average over a certain number of input samples by adding them together and then dividing the sum by the number of samples will reduce the noise level correspondingly.

If the number of samples in the average is adjustable over a certain range (say 2 samples to 20 samples), the resulting noise reduction can be fine tuned for different noise and input conditions. Noise can be filtered while not affecting the input signal of interest.

The next figures illustrate this averaging operation.

Noisy input signal with multiple alarm outputs

Averaged signal causes a single alarm output

Alarm Aggregation

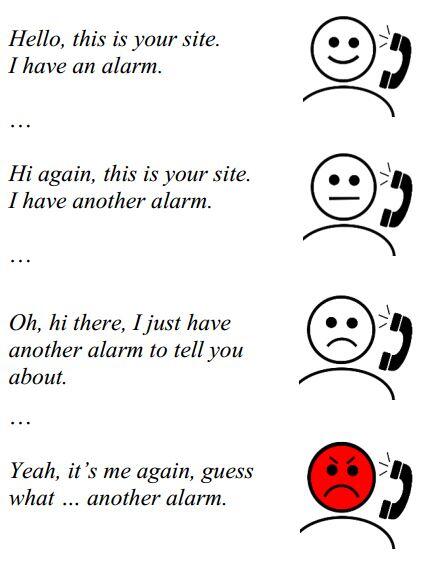

Alarms rarely seem to come alone.

Deglitching delays and filtering may all be set to different values to account for the varied characteristics of the inputs being monitored, thus a system could make many calls to send multiple alarms.

For example, suppose your microwave link went down, this would cause audio to be lost at the site input, which would then produce no audio at the site, and finally no output from the transmitter. Up to four different alarm calls to site maintenance personnel could result from this fault:

Being able to add a delay before actually transmitting the first alarm allows the different alarms to be consolidated into a single call.

The end result is much better!

Alarm Input Qualification

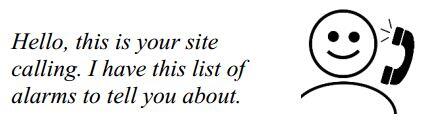

It is worth taking a moment to identify the key alarms that you want to present.

Let us say you have a power failure at your site. Depending on how you are set up, several sub-systems may stop working. The HVAC, tower lights, GPS time sync receiver, backhaul link, transmitter, and battery charger may all stop working and set off an alarm.

This means that your site maintenance people, or Network Operations Center, can receive six or more different alarms, all caused by the power failure. Having a smart “mute” function or Input Qualifier on all monitored inputs will allow you to mask this multitude of alarms and to only send one alarm, indicating the single cause that, in this case, is the power failure.

Use of such qualifiers can be used to mute different alarms

The example above uses the Power Fail alarm to mute other alarms, but any input should be useable to mute other alarms. Main audio could be used to mute audio sub-channel alarms, and these could then be used to cascade other mute functions.

This allows for the use of very flexible and smart alarm muting.

Alarm Redirection

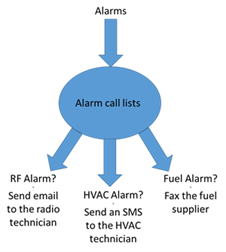

Depending upon the nature of an alarm, being able to redirect it to the proper resource can be a big time-saver.

For example, if the generator is running out of fuel, why not send the message directly to the fuel supplier instead of to the site technician, who would then have to call the fuel supplier himself?

This method does not actually reduce the overall number of alarms, but it does reduce the number of alarms sent to an individual who cannot take direct action on them.

The site maintenance technician’s workload is therefore reduced and this frees them up for more important tasks.

Having a system that can intelligently direct different alarms to different destinations is the key to this method.

One way of doing this is by using different alarm-call lists. List 1 can be dedicated to Radio alarms, and be set to call Technician A. List 2 can be dedicated to HVAC alarms and be programmed to call Technician B and so on.

A Better Result

As we have seen, de-glitching delays, hysteresis, signal averaging, alarm aggregation, intelligent alarm muting on root-cause, and alarm redirection are techniques that are useful to achieve these goals.

Using these different methods of reducing false alarms ensures that remote site management systems can be trusted and appreciated by maintenance personnel.

And all may have a good night’s sleep!

– – –

John Ahern is a co-founder and President of Davicom, a world-wide provider of remote monitoring and control systems. You can contact John at: john.ahern@comlab.com