My Transmission Line Can Hear!

[October 2024 ] When a lightning storm hits, it is a time when engineers and station owners hold their breath, hoping that nothing bad happens at the transmitter site. But, sometimes, things do happen. Here is Gary Minker’s version.

I got a call the other day from an old bibb overalls-wearing customer of mine with a nice little Country Music station that blows a paltry 100 kW in to the Ether.

This is a nice old guy who does know a thing or three about tractors, generators, farming, and now, to his amazement, transmission line.

THE BIG BOOM

The call I got was typical from him.

Him: “Hey, How y’all?”

Me: “What’s new?”

Him: “I seen somethin I never knowed.”

(… and this is where things went South…)

“I learnt a new thing. I was out to the transmitter the other day when a powerful big rain come up from the North and there was lightning. Man … there was lightning ever-where but the transmitter was a runnin’ good and I wasn’t worried about nothing till then it happened.”

Me: “OK, What happened?”

Him: “I saw a big old bolt of lightning and things was fine and then a few seconds later the boom come up on me and when the boom come up, the transmitter musta got scared cuz it shut off. My line can hear.”

This is pretty funny, but this is not the first time that I have heard this joke.

Still, my friend was not joking, and he was not too sure if the problem was the line or the transmitter. He said that the big box was humming along just fine and when the big boom hit the site, the box dropped to its knees and did not come back up.

I know this trick. I told him that I know this trick, and he probably has a problem with one of the 21 sections of rigid line or some of the multitude of joints or bullets. Likely the vibration from the lightning just rattled a bad joint and “pop goes the weasel.”

He of course being a down to earth farming kind of guy said that I could not be right. And this is where the bet for real money comes in.

THE BET

I told him that I was pretty sure that I knew what to do and that if he was willing, I would front the cost for the tower crew, bring them in, and prove to him that I was right.

If I was wrong, I would pay the total for the crew, dinner, and all my expenses. On the other hand, if I was right, he would pay for all that, more, and the parts to fix the problem.

The bet was more than he could walk away from, so we agreed to come back in two days and start at Midnight.

READY TO FRAM

We all met at the tower site on the appointed day, Krispy Kremes in hand, and I went over the game plan with the climbers.

“Go up the tower to the top-most joint under the antler. Take the line loose, put an EIA to Type “N” on the line along with a dummy and bring your one pound rubber mallet.”

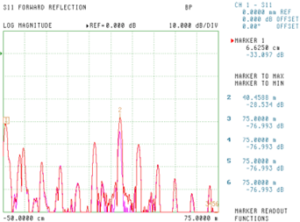

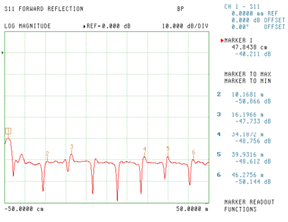

I warmed up the Vector Network Analyzer and performed a characterization on the line along with a “live over Memorex” trace that showed all 20 or so line sections, the joints and the insulators.

FRAM!

“OK,” I called up on the radio. “Fram the first joint with the mallet one time with a reasonable and repeatable amount of bang.”

Wham! There were no changes. OK, 1 down, 20 something joints to go. Going down to the next joint, Wham! Again, there was no change.

THE PROOF

Next, another Wham!

This time, the joint jumped 15 dB in Return Loss in Time (frequency) Domain. The colorful display of the red over the violet was all too clear to see. As the old joke goes: “that’s one,” I said. We repeated the banging all the way down the line and revealed 7 Krispy Kreme flaky joints.

Clearly the joints were all over the road for Return Loss and I knew that I had this fish shot in the barrel before it swam, but we started the diagnostic anyway since there was a dinner to be won.

Dinner was delicious.

CAUSE AND EFFECT

Transmission line in the best of conditions is not a forever kind of thing.

While there are a great many wave guide, coaxial, and Elliptical lines that have never given trouble – and are 30 to 50 years old – many rigid lines just do not give the trouble-free length of service for which one would hope.

Line Sweeping is a tool in the bag that can often locate discontinuities in the system that are about to be problematic. While I do admit that it occurs in the low single-digit percentages, line can always quickly fail right after a “house call” from the doctor. Also, rare as this may be, joint-based rigid slip bullet line goes through thermal cycles and shaves microscopic slivers of metal on a twice or more daily basis. And at some point, with the micro-arcing from this slippage, to quote Richard Pryor, fire can be inspirational.

As the joint degrades, any sudden vibration can trigger a larger than before arc at a connection which could set off an irreversible burn that only goes out after all the Teflon and brass have melted in to a puddle or dripped down the inside of the line.

The soot is tough to clean and all the molten beads of metal need to be found or the problem can happen again and again.

LINE SWEEPING

It is important to love your Line Sweeper.

While so many people claim to be a “certified’ Line Sweeper because they have an “Anritsu Card,” that only proves they know what buttons to push (on only a certain model of test apparatii), let alone competently interpret what the squiggly lines mean.

That is why you have to develop a relationship of trust with the person that you call Line Sweeper.

https://www.nautel.com/products/fm-transmitters/lpfm/

HOW IT LOOKS

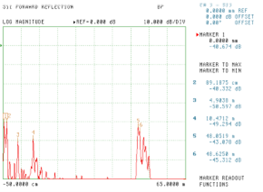

Different types of line, have a different, well-known, signatures.

Standard EIA type line has a positive going distinct bullet joint that also has the signature of a dent or other discontinuity. A similar result can be seen with the a close in view of SWR branded line.

The unique cup and cap joint yields a better Return Loss than does the standard EIA type flange joint. But when the joint fails, the same positive going result will be displayed as we saw in the red over memory violet trace.

Metal type coaxial products like Heliax or Helifiex are virtually discontinuity free except for the numerous small dents, kinks, and ground kit applications.

– – –

Gary Minker is president of Radio Works RF Consulting, in Lake Worth, Florida. He can be contacted at gary@radioworksrfconsulting.com or (561) 969-9245.

– – –

Would you like to know when more articles like this are published? It will take only 30 seconds to

click here and add your name to our secure one-time-a-week Newsletter list.

Your address is never given out to anyone.