Understanding LED Tower Lighting

[June 2024] For many stations, maintaining their broadcast tower(s) requires several different areas of expertise, from mechanical to electrical. This article will discuss why stations not using LED lighting should give it strong consideration in their next budget cycle. Not only are the latest models reliable, but the savings can make the conversion much easier.

Broadcasters with towers 200 feet and taller (or close to an airport traffic zone) all have at least one thing in common, the utilization of FAA obstruction lights.

Mandated by the federal government, these lights are the last line of defense for aircrafts to avoid collisions with towers, smokestacks and any other structures that protrude into the airspace. Obstruction lights indicate to pilots the presence of a structure in the airspace.

With those lights in place, pilots can determine how tall the structure is based on how many levels of the lights it has and approximately how far away from the structure their aircraft is. Then the pilot can determine the need to change course so as to not make contact with the structure or guy wires. What may seem like a hassle to station engineers and tower owners could potentially save lives.

LIGHTING SYSTEMS

The focus of this article is the most prolific types of FAA obstruction lighting systems, the A-style red beacon system.

The first obstruction lights that went into production were the incandescent marker lights and beacons. These lights typically consist of a cast aluminum base, red colored Fresnel lenses and two 620-Watt lamps for the beacons and 116-Watt lamps for the marker lights. The engineering, at the time, that went into these lights and lamps was very sophisticated and they met their needs for many years.

Of course, just like any form of technology, advancements have been made.

For example, several companies made xenon red beacons that have a crisper beam of light exerted from them. And just like the predecessor, these lights were the latest and greatest and served many stations for years.

MONITORING AND REPAIR

Although those lights served their purpose, they required constant monitoring and repairs.

Most older lighting controllers that turned the lights on at nights (when the light from the North was less than 35-foot candles) and made the beacons flash, were built either by station engineers or contactors.

There was a time when no two controllers were the same, and they all functioned slightly differently. Another disadvantage of many of the incandescent systems was their lack of monitoring to know when a beacon or marker light was out.

Some did have monitoring, yet it was almost unheard of to have remote system monitoring of any kind. Common monitoring would include an engineer keeping a log and physically inspect the lights every morning or evening to ensure proper function.

CURRENT MAINTENANCE CONCERNS

This takes time. Notification must be made of an outage to the FAA so a NOTAM can be filed.

Then someone, typically the station engineer, must find a reputable company that has all the certifications and insurance when maintenance is required. This too takes time – time out of their schedules. Usually, the station engineer also must be available at the site while the crew is performing the maintenance. And, once again, that takes time.

On top of that, station transmitters need to be reduced or turned off so crews on the tower are not affected by the RF – lessening the broadcast reach, or ceasing it completely, during the maintenance.

As you can see, all-in-all there are many behind-the -scenes costs associated with keeping up the lights. That is why the introduction of LED lighting has been welcome by many tower owners.

LED FOR MARKERS

In 1999, Dialight Corporation utilized their knowledge of manufacturing LED lights such as airplane cockpit indicators and industrial lighting and produced the first FAA approved LED marker light.

![]()

Dialight had seen the benefit of the long-life LEDs and thought, “what is a better place to put them than on the side of a tower several hundreds of feet in the air?” The result was the 860 Series (shown to the left).

These marker lights eliminated the need to have a climber go up and the change marker lamps every year to two years, for which any station knows is a must with

incandescent lights. It is also expensive, especially as labor and insurance costs have risen.

LED BEACONS

Seeing the success of the 860 series LED marker light, Dialight got back to work on LED Obstruction lighting.

They launched the first LED L-864 beacon in 2001.

The size of this new beacon was comparable in size to the incandescent beacon, yet they differed in the fact that, unlike the incandescent lights, there were no replaceable parts in the light and therefore would last a decade maintenance free – a total game changer in the tower world.

Plus, owners and engineers finally had a complete LED tower lighting system that could be used on their tower.

REDUCTIONS IN MAINTENANCE TIME AND COST

Benefits of the new LEDs were seen immediately.

The wiring for the beacons were significantly smaller than it was for the incandescent. LEDs draw approximately 2% of the Watts that it took to run the incandescents! You also did not have to worry as much about the Voltage drop up to the beacons. And, with smaller wire, smaller conduit could be run up the tower so the tower load was greatly reduced.

Perhaps most importantly to the owners, the drop in cost to run the system was another immediate benefit.

First of all, the 2% of Watts these LEDs were utilizing compared to the incandescent, reduced about 98% cost of electricity to run the systems. But perhaps the biggest difference was the need to have climbers on the tower every year to re-lamp was gone.

Furthermore, aside the fact that climbing crews are not cheap, there are a lot of other factors to consider and budget for when someone must climb the tower to do maintenance, including physical maintenance of the tower and painting it.

EVEN MORE TECHNOLOGICAL ADVANCES

As of 2024, Dialight – and other LED manufacturers – have made several more advancements in their LED obstruction lights.

Dialight is now on the 6th generation of L-864 beacons. The newest beacons, the model D664R13001s, are now 8.5-inches tall and weigh only 18 pounds.

This version (D664R13001) of the L-864 beacon has infrared (IR) LEDs included in them as that became an FAA requirement on all new systems in 2019 (the -43J specifications). These smaller beacons have a reduced wind load and even less current draw than the older generation beacons.

The current marker lights also have a smaller profile than the original ones at 6-inches tall and 2 pounds for the single units. They draw only 5 Watts when set for steady burning. The draw is even less when configured to the new -43J specification that requires L-810 marker lights to flash when they are required to be in the system.

RUGGED, LONG-LASTING LIGHTS

A few other benefits of the Dialight LED red light systems are that they are designed to survive and thrive in harsh conditions, whether that be very hot and humid places or very cold and icy places.

The Dialight lights we have used now have a 15+ year expected maintenance-free working life – and some systems have already exceeded 15 years.

Additionally, if the system is installed by a certified installer like Fuellgraf Chimney & Tower, instead of a 5-year parts warranty, there is now a 7-year parts warranty. This is the longest warranty in the industry.

NEW LIGHT CONTROLLERS

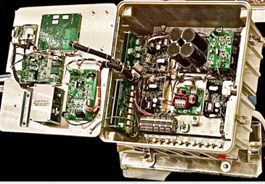

One of the greatest advancements in the FAA lighting systems, though, is the controllers and INEM remote monitoring.

Dialight has standardized and manufactured their own controllers so the days of going into repair a controller “blind” are gone. The new controllers have the capability of a single controller for all systems, and you can program it to any A configuration.

Now it is easier to meet the FAA -43J specifications.

They state that any towers that have two or more levels of flashing red beacons can remove the L-810 steady burning marker lights from their systems. For towers that have a single beacon on the top, you are still required to have a level of L-810 marker lights, but the FAA wants them to flash in sync with the beacons now, so as to not confuse migrating birds that may fly into the tower.

Dialight has all the options to either use or not use L-810s and either flash them or keep them on steady. This is a programming option so that any configuration in a one-off situation can be accomplished.

INDICATORS, ALARMS, AND REMOTE MONITORING

Besides the programming options, the Dialight controllers have both visual mode and alarm indicators, along with both an alarm log and event log that give you date and time stamps of events.

The logs can be downloaded via Ethernet or WiFi, even to your smart phone, and include mode changes, alarms, and whether or not they are active or have cleared out.

The ability to run a quarterly lighting inspection (QLI) with the push of a button is available. This test, as required by the FAA at least once every four months, will ping every light and every function of the system, cause it to fail, and then restore it. This ensures that actual failures are recorded and reported and that when the lights are functioning 100%, you do not get false alarms.

If the screen at the end of the QLI pops up “QLI PASS :)” your system is working perfectly and to FAA requirements.

Nautel.com

REMOTE MONITORING

The controllers have the traditional dry contact alarms to tie into existing alarm and control monitoring the station has at the site but, for a minimal up-front cost, you can add Dialights INEM remote monitoring.

This program lets you utilize all the functions of the controller, including the QLI, from anywhere you have Internet.

The best part is, once you have the equipment, plug in the existing ethernet at the site to the circuit boards – and that is it. Dialight does not charge a subscription fee like most other manufacturers do.

WHY WE CHOSE DIALIGHT

We understand that there are many service companies to choose from and several manufactures to consider when you are looking at upgrading your FAA obstruction lighting. We recommend that in deciding the best approach, you do a cost-savings analysis based on your particular tower layout and heights.

Fuellgraf Chimney & Tower, Inc. has chosen to align ourselves with Dialight because they were the first to advance the technology to LEDs. More importantly, they make a very reliable light – and stand behind their products.

Our certified crews have installed thousands of Dialight systems all over the United States, on 150-foot AM towers to 2000-foot FM/ TV towers to nuclear power plant cooling towers – and everything in between.

– – –

From its founding in 1946, four generations of the Fuelgraf family have provided tower and lighting services to their clients from Gallatin, TN. Their way of operating is that they plan and do the work correctly, to code and manufactures specs, and will not leave until the system is 100% and the customer is completely satisfied.

If you would like a proposal, including provide all the data sheets, a cost savings analysis, and a list of references, visit their website, call them at 800-621-4419, or connect via email.

– – –

Would you like to know when more articles like this are published? It will take only 30 seconds to

click here and add your name to our secure one-time-a-week Newsletter list.

>Your address is never given out to anyone.