Watts to Save

[May 2016] We are headed into Summer here in the Northern Hemisphere. Each day, more air conditioners are starting their yearly activity. Of, course, each year, power costs seem to raise a little more. That makes it a good time to offer some ways to analyze an important part of most stations’ budget load.

A major area where the Engineering Department can save the station on expenses is on its electric bill.

In fact, this is a big opportunity that engineers should grab by the horn and show the GM that your department can also contribute to the income side of the business. Remember: money saved is money earned.

Understand Your Bill

Periodically, you should look at and understand the electric power bill, both for the transmitter site as well as the studio and offices. Start by getting in touch with the electric company and get the rate schedules being used for your facilities.

Aside from the correct account number and details like that, there are a few parts of the bill with which you should be familiar.

- The energy in kilowatt hours (kWh – the power consumed by the facilities during the last billing period.

- Any “demand charge” – for the capacity required by the facilities for that billing period. This varies according to how energy is used, and will be explained later on in this article.

- Exactly what rate plan under which you are operating.

- The rate tiers – what happens to the rates as power consumption goes up.

Check Your Rate

Remember: the power company has multiple rates – everyone does not pay the same rate. This means that changes in your consumption (either up or down) may qualify you for a different rate structure. And the power company does not always tell you that another rate might be more advantageous.

Many stations have found conversion to solid state transmitters has made a big difference in transmission site electrical. In addition to savings from more efficient transmitters, the reduction in heat load often brings additional savings from reduced air conditioning. (Interestingly, at some sites, the lack of exhausted transmitter heat in winter may spotlight the need to better weatherproof the building!)

TV Can Save a Lot

Television facilities, in particular, found the change to digital transmitter equipment in order to replicate the analog coverage has lowered the facility power consumption.

For example, if you were using 217 kVA (kilovolt/Amperes) before – and were charged under the Large User Rate – but now have lowered consumption down to 80 kVA, it may be possible to change the rate charge to General Usage Rate. These are actual figures, by the way, from one of our facilities.

To accomplish this it helps to ask for the Usage History of the facility from the power company. This document will establish the drop in usage after the solid state conversion. Using the power company’s Rate Schedules, check to see if your present usage is already on the proper Rate. If not, then it is time to ask the utility company to adjust your rate accordingly.

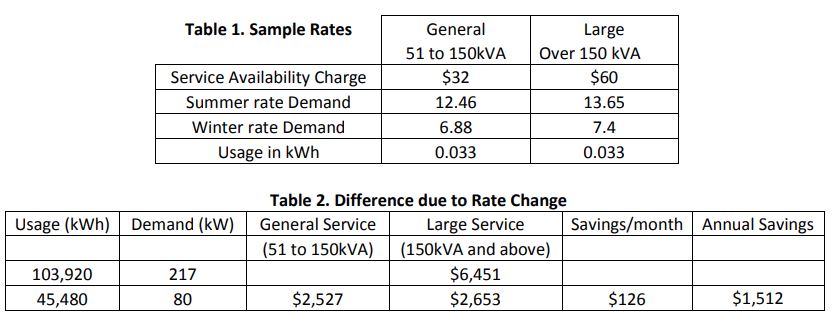

Using the Rate Schedule of an actual power company as an example on Table 1, we can compute for the difference on the bill applying both rates as shown on Table 2.

You might want to take note in Table 2 that the usage, of 103,920 kWh during the simulcast of analog/DTV operation, dropped to 45,480 kWh when the analog was retired. Thus there was an immediate savings in the power bill even using the Large Service rate.

However, an additional of $126 per month was still realized by just applying the correct General Service rate. This is $1,512 in annual savings by just getting the correct rate applied to the bill. It may not look much as far as the station earnings is concerned but think of it as a tax refund and it will suddenly look like something worth the effort.

Of course, if you are in an area where the electrical rates are more like the national average of 10 cents or so per kWh, savings now jump past $4,500 a year – not too shabby at all.

If you have not done so as yet, check with the power company and inquire if your rate has been adjusted to reflect the current load of the transmitter facility. You may be surprised to find out you are still being charged at a rate that no longer applies to your usage patterns.

After all, why pay higher rates than you should be charged for?

Demand Need Not Be So Demanding

Electric utilities determine the peak usage of your facility usually by measuring the 15- minute period of highest usage. This is the basis for the Demand Charge.

The Demand Charge part of the bill may cost as much as 40% of your bill so it is important to seek ways to lower this. It is a good idea to verify with your utility company as to the how they determine the demand factor for a particular locality, as this may be different from place to place.

Suppose the biggest loads in your facility are a 10 kW transmitter and two units of 15-ton HVAC. There is not much you can do but run the 10 kW transmitter as scheduled to be on the air, but both of the two HVAC units need not work at the same time for the same 15-minutes, or more.

If both HVAC units do work at the same time for 15 minutes or more, the facility Demand Charge goes up. On the other hand, if the HVAC units are operated alternately by adjusting the thermostats accordingly, then the facility demand is lowered as if your loads are just the transmitter and one HVAC unit. So load scheduling may be a strategy you can employ to lower the Demand Charge.

Similarly, testing your auxiliary transmitter can be quite expensive. A 50 kW auxiliary transmitter, for instance, will almost certainly push you over into a higher rate bracket. Stations that must deal with this situation quickly learn to start and transfer to the generator before starting the auxiliary transmitter. (Of course, you now may need to deal with clean air regulations.)

You will need to experiment on this at your facility to find what settings work best, depending on the various loads and time of the year. It is simply the responsible way of managing the transmitter site.

Avoid Power Factor Charges

By the way, some electric utilities are now penalizing users if the power factor is less than 0.96. There is usually a graduated scale where additional charges are added on your bill depending on how bad the power factor is measured.

It is better to invest a few thousand dollars on correction capacitors to bring up the power factor to 0.98 than to pay for the penalty. Any money spent on fines or penalties is definitely a waste.

Non-Adjustable Adjustments

Here is one more thing to note when going over the monthly power bills.

It concerns a line on the electric power bill that engineers cannot do any-thing about. This line is called “Adjustments.”

“Adjustments” refers to fees passed onto the power company to be paid for by the consumers. There are times these adjustments cause the bill to go up as if there was an additional load that suddenly used up a significant amount of electricity at the site.

So, when you are asked by the bean counters of the station why the electric bill suddenly jumped up that month, look for any of these adjustments first before running out to the site to investigate.

Efficiency Check

Efficiency is the key word here.

Careful design of the transmitter building is important. Always think of the big picture.

For example, do not forget that when manufacturers talk about how efficient their transmitters are, they may not tell you how much HVAC capacity is needed, often driving the whole facility power usage up.

All too often, HVAC requirements are calculated considering the transmitter heat alone. It is entirely possible that half of the cooling requirement is from heat seeping through the building roof and the walls, particularly during summer.

Use only energy efficient equipment in your facility. This brings into mind those indoor power controllers for the tower light system. A 1200-foot tower using 12 strobes may have nine of the power controllers inside the building. The heat generated by these power controllers may be equivalent to having another transmitter inside the room. Make sure to account for such cooling need in the facility design.

Energy Saved is Money Earned

One area where attention to energy conservation is usually left out is heat insulation of the ceiling and walls.

Even though analog is gone for TV, there are still potential changes to more power efficient equipment.

It is understandable that transmitter buildings have so much ceiling-mounted hardware like filters, cable trays and waveguides that it makes it harder to place heat insulation on the high ceiling. However, these ceilings and walls contribute a lot to the HVAC requirements and should be considered in the facility design.

Install automatic door closers on all doors to keep them closed. This is a cheap and simple way to keep cool air inside the building. Plug all openings and other measures to keep cool air inside the building.

Similarly, in winter without the large heat discharge from tube transmitters, you might need to invest in room heaters if the building is not properly insulated, running up the power bill.

This time, the automatic door closers and other measures will keep the heat inside – better for you and the transmission system.

A Solid State Transmitter Tune-Up Can Help, Too!

Solid state transmitters utilize a number of combiners to come up with the needed TPO (Total Power Output).

Aside from the Class AB operation, these combiners and reject loads are main culprits why solid state transmitters can be low in overall power efficiency.

Depending on the transmitter make and model, you can minimize the power wasted on Reject loads of the combiners by tweaking individual the PA modules such that the TPO remains at 100% with good SNR (Signal to Noise Ratio). Some exciters can do a great job in non-linear equalization that you can lower the driver output and the individual PA module FWD (Forward power) and still have 100% TPO.

Lowering the FWD with correct phasing lowers the REF (Reflected Power) which, in turn, lowers the Reject power wasted. Proper phasing of the PA module outputs help in minimizing the power wasted on the reject loads.

So if the transmitter operates conservatively, with less heat dissipated on the reject loads and the LDMOS heat sinks, then less cooling is required. Spend some time tuning your solid state transmitter to find that sweet spot of good SNR and minimum drive and PA module FWD to keep that 100% TPO. If the PA modules run cooler, you are extending their life, too!

If all of us watch the Watts we use and save, we not only will save the station from unnecessary expense but have done the planet a favor as well.

– – –

You can contact Romualdo “Rolin” Lintag, CSTE, at: rolin_lintag@yahoo.com